UHP is short for Ultra High Power and stands for ultra high power graphite electrode category. UHP graphite electrode using high-level needle coke production, graphitization temperature up to 2800 ~ 3000 ° C, graphitization in a string of graphitizing furnace, heat treatment, then its lower resistivity, small linear expansion coefficient and good thermal shock resistance make it won't appear crack and break, allowed by current density, shortening time of smelting and improving production efficiency. UHP is suitable for ultra-high power electric arc furnace of 500~1200Kv.A/t per ton.

Products Describe

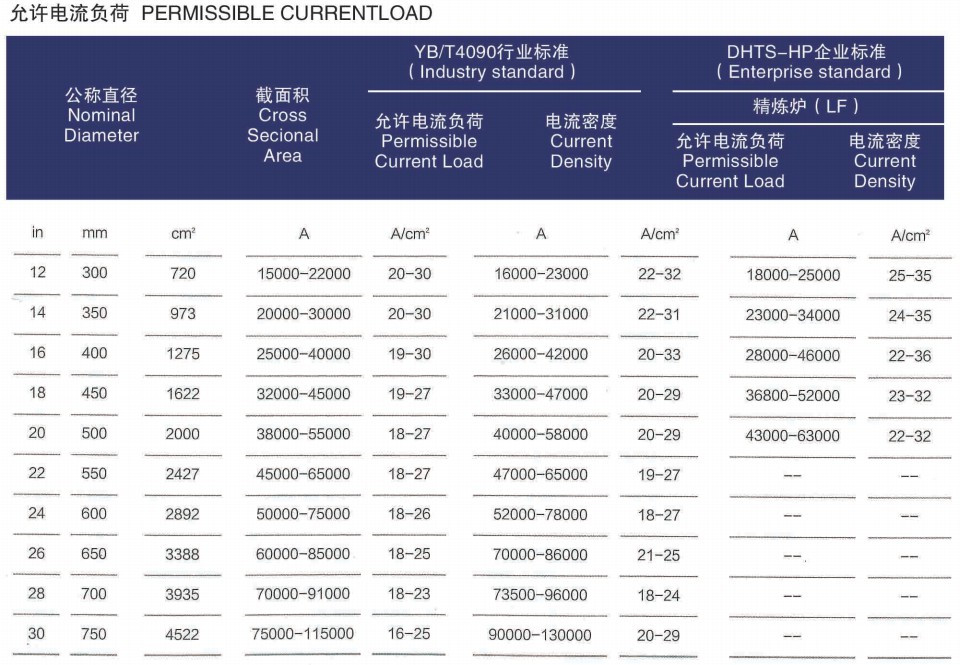

UHP graphite electrodes are graphite electrodes that allow the use of current densities greater than 25 A/cm and are mainly used in UHP steelmaking electric arc furnaces.

The unit consumption of graphite electrodes is less, and the production cost is reduced to a certain extent. For example, assuming that there is no production stoppage in a steelmaking plant throughout the year, the first-level LF refining furnace will consume about 35 graphite electrodes per week. Based on the consumption of 165 furnaces in refining production, after adopting the graphite electrode anti-oxidation technology, it can save 373 (153t) electrodes, which, calculated at 16,900 yuan per ton of ultra-high power electrodes per year, can save 2.5857 million yuan.

Graphite electrodes consume less power, which saves electricity consumption and production costs per unit of steelmaking.

Because the graphite electrode is replaced less frequently, the labor load of the operator is reduced, the risk factor of operation is reduced, and the production efficiency is improved.

Graphite electrodes are low-consumption and low-pollution products, which have very important social significance in today's advocacy of energy conservation, emission reduction, and environmental protection.

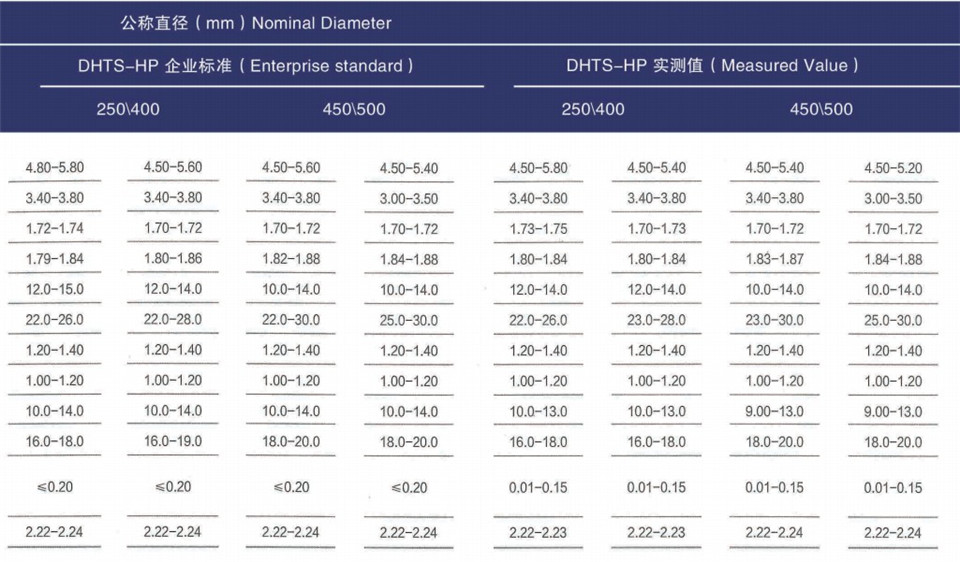

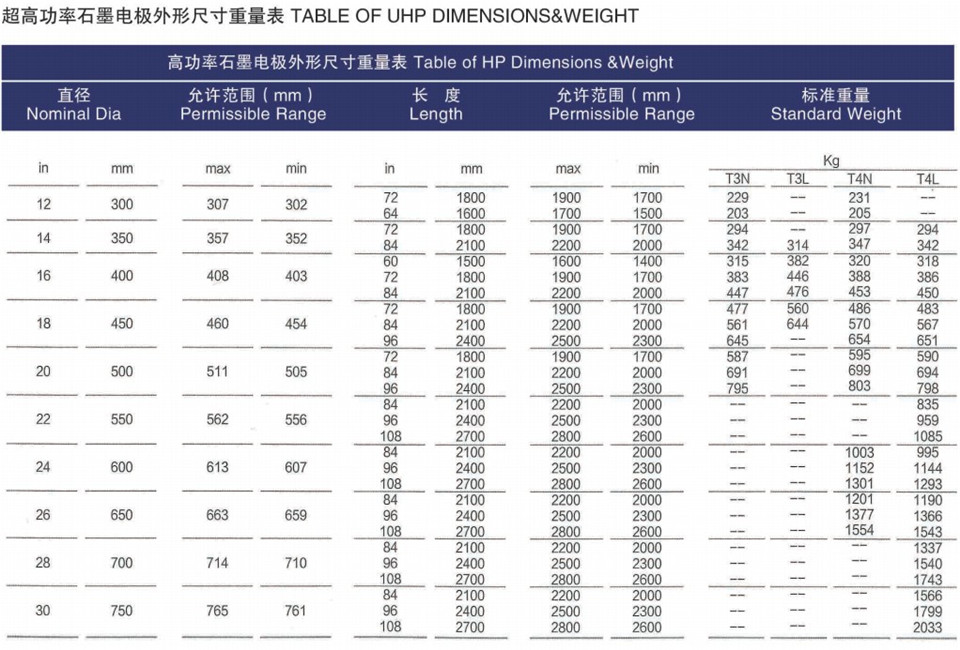

Product Parameters

Packing and Shipping

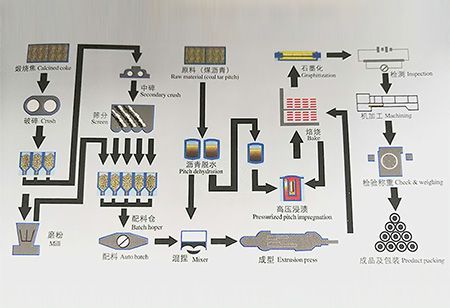

Production and Inspection Process

FAQ

1. How about production?

A: High output, annual output of 80,000 tons, timely delivery; Guaranteed delivery date.

2. How to ensure quality?

A: Always pre-produce samples before mass production; Always carry out final inspection before shipment;

3. What can we buy from you?

A: Graphite electrode, electrode paste, carburizer, carbon products and other graphite products.

4. How to determine the grade of graphite electrode?

A: Please send us an inquiry and our sales manager will confirm the details and prices for you.

Customers will be asked to provide EAF parameters and electrode specifications and dimensions

Inquire Basket (0)