In the process of steelmaking and casting, due to factors such as poor batching or mixing and too much decarburization, sometimes the carbon content in steel or iron does not reach the expected standard. At this time, it is necessary to add carbon to the steel or molten iron.

Therefore, the quality of the recarburizer directly affects the quality of the molten iron, and also directly affects whether a good graphitization function can be obtained. In short, carburizers play a vital role in reducing the shrinkage of molten iron.

Graphitized recarburizer for foundry is a product used to increase carbon (C). It is used in many industries. Adding recarburizer during steelmaking can effectively improve the hardness and wear resistance of steel, but if improper handling causes too much carbon in the steel, it will also affect the quality of the steel. Therefore, it is very necessary to analyze the problems that should be paid attention to when using the carburizer. After sorting out, we can effectively improve the use function of the carburant.

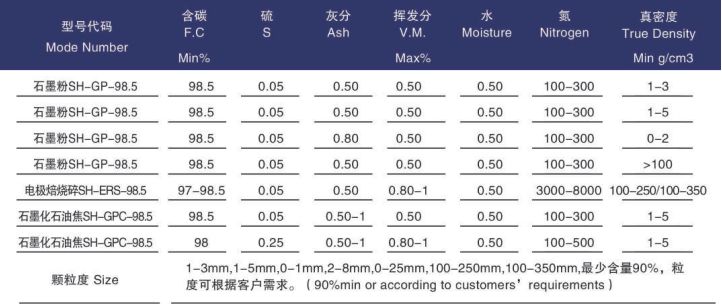

Product specifications: 0-1mm, 1-3mm, 3-5mm, 5-30mm, product granularity required by customers, our factory can process it, and guarantee the quality.

Products Describe

There are many kinds of raw materials for carburizers, and the production processes are also different, including woody carbon, coal carbon, coke, graphite, etc., among which there are many small types under various classifications. High-quality recarburizers generally refer to graphitized recarburizers. Under high-temperature conditions, the arrangement of carbon atoms is in the microscopic form of graphite, so it is called graphitization.

Graphitization can reduce the content of impurities in the recarburizer, increase the carbon content of the recarburizer, and reduce the sulfur content. The carburizer is used in casting, which can greatly increase the amount of scrap steel and reduce or eliminate the amount of pig iron.

In the feeding method of electric furnace smelting, the recarburizer should be put in together with scrap steel and other furnace materials, and small doses can be added to the surface of molten iron. However, it is necessary to avoid feeding a large amount of materials into the molten iron to prevent excessive oxidation, resulting in insignificant carburization effects and insufficient carbon content in castings. The amount of fuel added is determined according to the ratio and carbon content of other raw materials.

For different types of cast iron, choose different types of recarburizers according to your needs. The characteristics of the carburizer itself select pure carbon-containing graphitized substances to reduce excessive impurities in pig iron, and the appropriate choice of carburizer can reduce the production cost of castings.

Product Parameters

Packing and Shipping

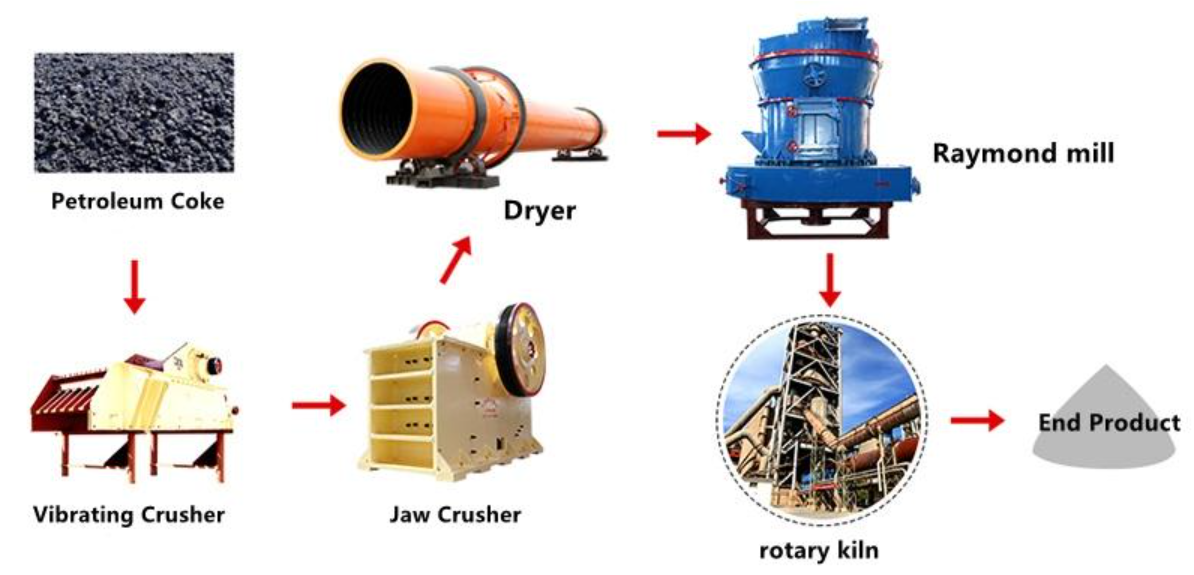

Manufacture Process

FAQ

1. What's your advantage?

A: Honest business with competitive price and professional service on export process.

2. How I believe you?

A: We consider honest as the life of our company, your order and money will be well guaranteed.

3. Can you give warranty of your products?

A: Yes, we extend a 100% satisfaction guarantee on all items. Please feel free to feedback immediately if you are not pleased with our quality or service.

4. Where are you? Can I visit you?

A: Sure, welcome to you visit our factory at any time.

5. How about the delivery time?

A: Within 15-30 days after we confirm you requirement.

6. What kind of payment does your company support?

A: T/T, 100% L/C at sight, Cash are all accepted if you have other payment, please contact me.

Inquire Basket (0)