Home > Products > Calcined Petroleum Coke (CPC) > CPC Calcined Petroleum Coke as Carbon Additive Carbon Raiser Carburant

Calcined petroleum coke is a kind of petrochemical product, whose raw materials is green petroleum coke. It is widely used to produce graphite electrode, graphite blocks, brakes pads and other carbon products.It can also be used as carbon additive in some steel and aluminum plants, another, it is used in refractory, insulation, filler, etc.

The main use of CPC is in the production of anodes for the Aluminum Smelting process. 70 - 80% of CPC is for the Aluminum Industry. The reason for use in the Aluminum Industry is for conductivity.

Products Describe

The role of carburizer

Cast iron and cast steel castings will have a requirement for carbon, so the carburizer, as the name implies, is to increase the carbon content in molten iron. For example, the commonly used furnace materials in smelting are pig iron, scrap steel, and recycled materials. The carbon content of pig iron is high, but the purchase price is higher than that of scrap steel. Therefore, increasing the amount of scrap steel, reducing the amount of pig iron, and adding carburizers can reduce the cost of castings to a certain extent.

The use of carburizers can not only make up for the burning loss of carbon in the process of iron and steel smelting and ensure the carbon content requirements of specific grades of steel, but also be used for post-furnace adjustments. As an important raw material for melting molten iron in an induction furnace, the quality and usage of recarburizer directly affect the state of molten iron.

Adding a specific brand of recarburizer to the ladle after slag removal and degassing treatment can adjust the carbon content in the ladle to achieve the purpose of multiple numbers in one ladle. The materials used in the recarburizer mainly include graphite, graphite-like materials, electrode blocks, coke, silicon carbide, and other materials. Commonly used electrode blocks and silicon carbide recarburizers have the advantages of high carbon content and strong oxidation resistance, but the production process is relatively complicated and the cost is high. Coke powder and graphite are used as recarburizers, and the production cost is lower than that of electrode blocks and other materials, but the content of ash and sulfur is high, the content of carbon is low, and the carburizing effect is not good.

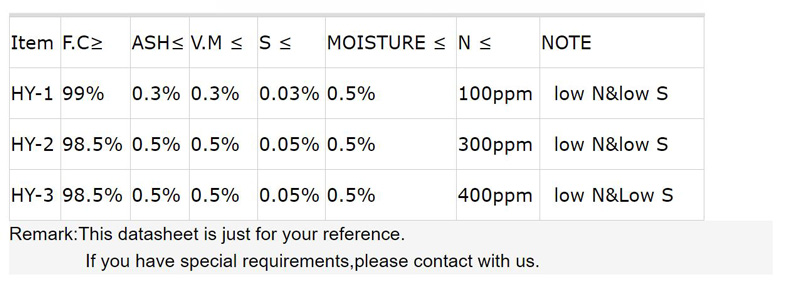

Product Parameters

FAQ

1. Do you provide free sample?

A: Yes, we can provide free sample if we have in stock, just need you to cover the delivery cost.

2. Do you have stock?

A: We understand most customers prefer stock, so we'll try to keep stock for most products. However, for some rare products, we won't keep stock and it needs time to synthesize.

3. Are you a manufacturer?

A: Yes, We are the manufacturer in this industry for more than 10 years.

4. Why should I choose you?

A: 10 years experience in chemical industry.

Supply Full range of chemical material.

Consistent Quality. Our plant has strict quality control in each manufacturing process. And Our goods passed SGS which quality can be control and guaranteed.

Most competitive pricing.

l Respond in 24 hours to inquiry, feedback or other requirements.

Inquire Basket (0)